It Began In Early-1900s Genoa

In the late 19th century, the riviera between Portofino and Marseille was regarded as the world’s best soap-making region. Enticed by the excellent quality raw materials, Virgilio Valobra opened his factory in Genoa in 1903. He was keen to preserve the heritage of master soap-makers’ technical skills and continue the tradition of fine artisan toilet soaps made with exceptionally pure ingredients.

Over 100 Years In

The Art of Soap-Making

Each Valobra soap requires crafting for over 2 months before it reaches your hands. Why? Because there is no other way to make quality soap. Unlike industrial soaps, all Valobra soaps are made using the traditional ‘full-boiled’ or ‘Marseille’ manufacturing process, a time-consuming procedure that is as old as it is romantic. Each stage is essential in contributing to the quality of the soap.

See How It’s Made

Pure Soap

Obtained from a mixture of 3 simple ingredients (soda, coconut oil and tallow), it guarantees full, deep cleansing of the skin in full observance of the skin’s pH. The manufacturing method uses the ‘levata da lisciva’ technique, which involves separating the soap from its reaction by-products. The result is a pure soap, free from impurities, and ready to be enriched with high-quality cream and scent ingredients.

Ergonomic Shape

The shape of the Valobra soap is the result of careful design. A shape that arose from the engineering of experience. An item that the hands welcome in a perfect, pleasant grip that releases a fragrant, dense and enveloping lather when touched. This perfect ovoid is the ideal shape for a bar of soap, as it nestles seamlessly in the palm, allowing it to be cupped evenly using both hands.

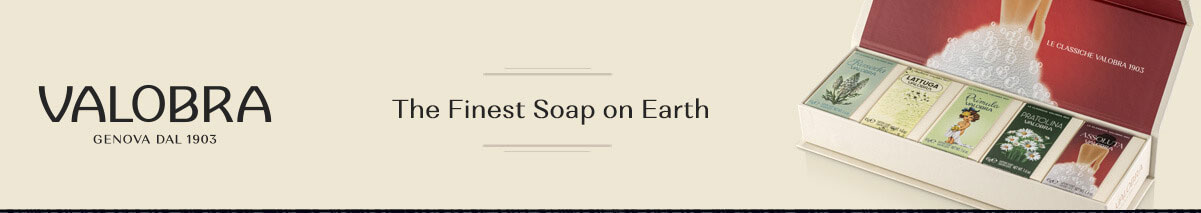

Artfully Crafted Packaging

Valobra soaps are true collections of creativity that become items of design. The historical creations were designed by artists from the early 1900s. Each bar of soap is hand packaged with care.

View Valobra Products

It Began In Early-1900s Genoa

In the late 19th century, the riviera between Portofino and Marseille was regarded as the world’s best soap-making region. Enticed by the excellent quality raw materials, Virgilio Valobra opened his factory in Genoa in 1903. He was keen to preserve the heritage of master soap-makers’ technical skills and continue the tradition of fine artisan toilet soaps made with exceptionally pure ingredients.

Over 100 Years In

The Art of Soap-Making

Each Valobra soap requires crafting for over 2 months before it reaches your hands. Why? Because there is no other way to make quality soap. Unlike industrial soaps, all Valobra soaps are made using the traditional ‘full-boiled’ or ‘Marseille’ manufacturing process, a time-consuming procedure that is as old as it is romantic. Each stage is essential in contributing to the quality of the soap.

See How It’s Made

Pure Soap

Obtained from a mixture of 3 simple ingredients (soda, coconut oil and tallow), it guarantees full, deep cleansing of the skin in full observance of the skin’s pH. The manufacturing method uses the ‘levata da lisciva’ technique, which involves separating the soap from its reaction by-products. The result is a pure soap, free from impurities, and ready to be enriched with high-quality cream and scent ingredients.

Ergonomic Shape

The shape of the Valobra soap is the result of careful design. A shape that arose from the engineering of experience. An item that the hands welcome in a perfect, pleasant grip that releases a fragrant, dense and enveloping lather when touched. This perfect ovoid is the ideal shape for a bar of soap, as it nestles seamlessly in the palm, allowing it to be cupped evenly using both hands.

Artfully Crafted Packaging

Valobra soaps are true collections of creativity that become items of design. The historical creations were designed by artists from the early 1900s. Each bar of soap is hand packaged with care.

View Valobra Products